Mixer Knives: Which Style is Best For You (2021)

November 4, 2021 | Ag Parts

Here at Kooima Ag, we are the mixer knife experts. We pride ourselves in making the fastest and sharpest cutting knives on the market. We make all of our mixer knives in our facility in Rock Valley, IA. We test them multiple times to ensure that you are getting the best knives for your application.

Part 1: What are the different style options of Mixer Knives?

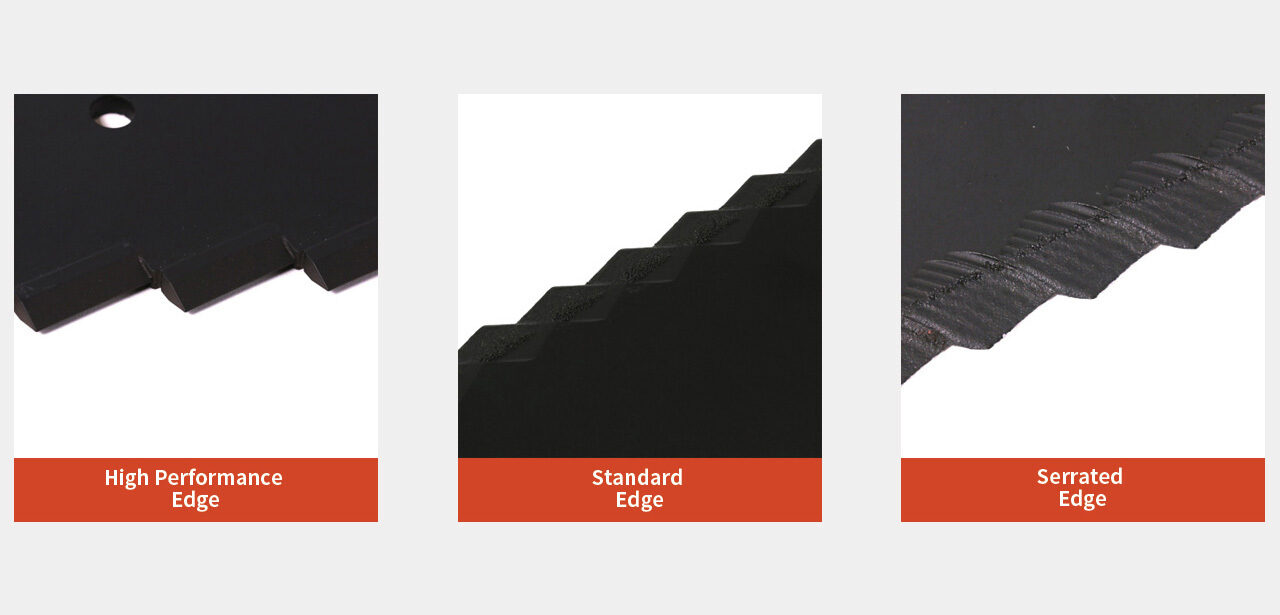

We offer three different style options of Mixer Knives: our Standard Mixer Knife, High-Performance Mixer Knife, and Serrated Mixer Knife. The Serrated Mixer Knife includes both Serrated Edges or Serrated Insert Styles. Our different styles help provide you with the best cut for mixing needs.

Part 2: What are the advantages of each style of Mixer Knives?

Standard Mixer Knives are made of heat treated, high carbon steel. They also have a tungsten carbide cutting edge. High-Performance Mixer Knives feature Kooima Ag’s exclusive patented tungsten carbide insert cutting surface or an extra-thick layer of tungsten carbide coating for unsurpassed performance.

These knives are great because they last longer! Serrated Mixer Knives are designed with serrations on each individual point giving them a more aggressive cutting edge. These knives are perfect for faster cutting!

Part 3: How do you know which style Mixer Knife to choose for you operation?

At Kooima Ag, our many options of mixer knives offer you a choice for your operation. For mixing or cutting wet hay or other products, we recommend using our High-Performance style knives in the bottom four positions.

Then, you can use Standard Mixer Knives on the top of the auger. We also highly recommend using our Serrated Edge style knives, they come in both, Standard and High-Performance.

Part 4: Are Mixer Knives easy to install?

Mixer Knives can be easy to install. If each time you get new Mixer Knives, you replace the bolts it will be easier to change out your knives the next time. All of our High-Performance Mixer Knives last longer than OEM, so we also recommend using grade 8 bolts in your mixer wagon. This will also help with the bolts turning out easier.

Part 5: Are Kooima Ag Mixer Knives better than other brands?

Kooima Ag mixer knives are made right here in Rock Valley, Iowa. We have experienced engineers and operators on staff, we have also been making knives for over 30 years. We have an in-house metallurgist that ensures our knives are the best quality possible. Our customers prefer Kooima Knives™, sharper knives that save you time, fuel, and money!

Part 6: What is the lifespan of a Mixer Knife?

The lifespan can range on mixer knives, it depends on the size of your operation and what ration you are putting in your mixer. Most Standard Mixer Knives last 6 months and we have consistently seen High-Performance Mixer Knives last 2-3 times longer.

The knives located at the bottom of the auger will wear out sooner that those at the top. This is due to the fact that most of the cutting is done by the bale restrictor so the knives located in that area will wear out faster.

Part 7: What is the advantage of buying replacement knives over OEM knives?

Since we at Kooima Ag make our knives right in our facility, we are able to keep the costs down. We manufacture, stock, and ship the mixer knives directly to you, the customer. You don’t have to go through a dealer to get your parts, you can come Factory Direct to Kooima Ag. Doing this will save you time and money.

Part 8: Who can I contact to get more information about Mixer Knives?

Contact any of our friendly sales representatives here at Kooima Ag. You can reach us at 800-522-8874 or email us at sales@KooimaAg.com to ask questions or get your mixer knives today! Find all of our Mixer Knives Here for easy online ordering. Kooima Ag – Your Mixer Knife Experts.